Hybrid cloud approaches for resilient control systems

Hybrid cloud strategies combine on-premises control with public cloud services to increase resilience, flexibility, and operational visibility for industrial control systems. By distributing workloads between edge devices and cloud platforms, organizations can maintain local control under constrained network conditions while leveraging cloud analytics for predictive maintenance, energy optimization, and supply chain monitoring.

How does edge computing support resilience?

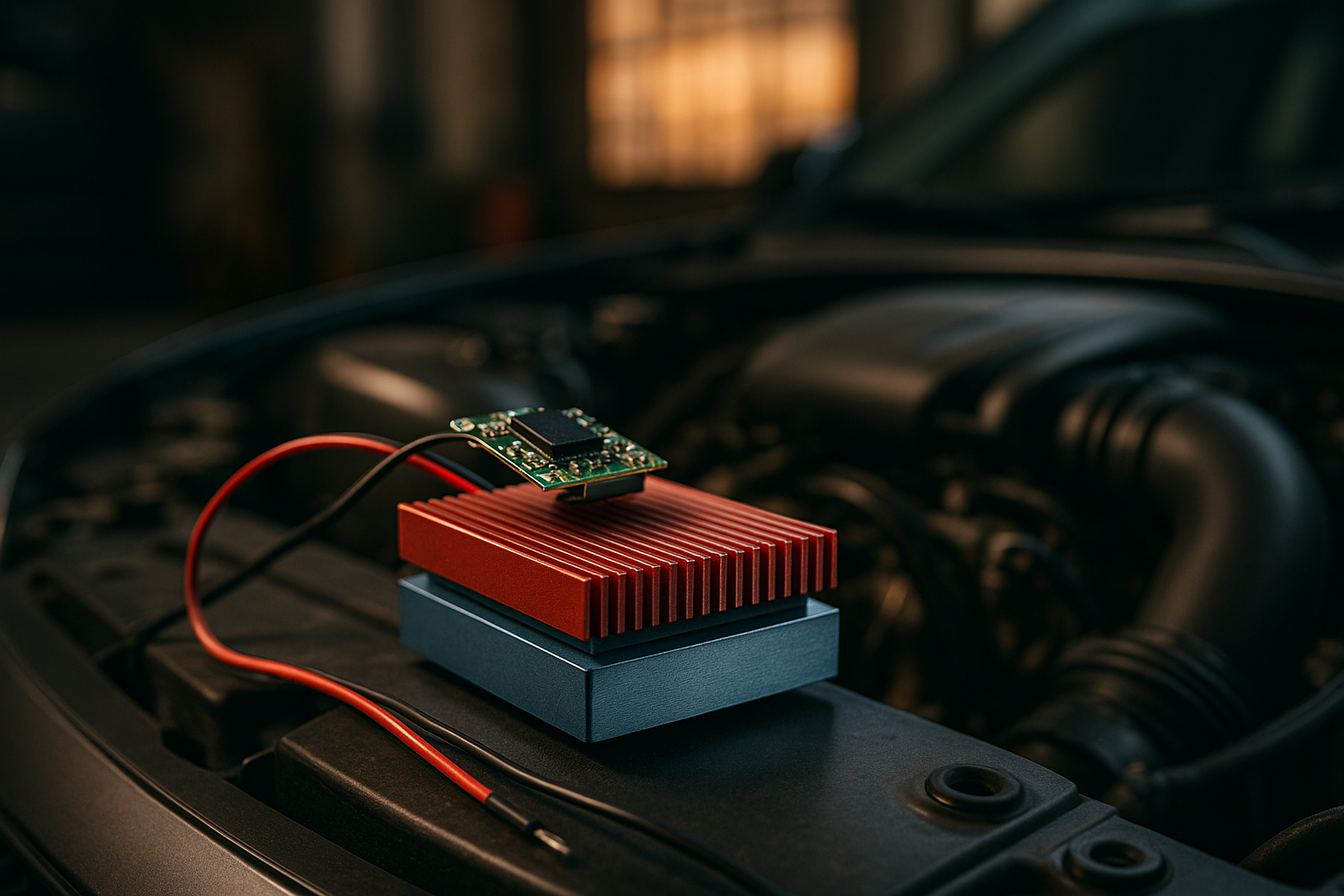

Edge computing places processing close to control systems and sensors, reducing latency and preserving local decision-making when connectivity to central systems is degraded. For resilient control systems, edge nodes can run real-time monitoring, basic analytics, and safety logic so automation continues even during intermittent cloud access. This local capability helps maintain throughput and manage inventory flow at production nodes while ensuring critical control loops remain responsive.

Edge deployments also enable selective data forwarding: high-value telemetry is sent to the cloud for deeper analytics while routine control stays local. That split reduces bandwidth use and supports energy-aware operation by avoiding unnecessary remote processing, improving overall system availability.

What role does cloud integration play?

Cloud platforms provide scalable analytics, long-term storage for historical monitoring, and centralized orchestration across distributed control sites. Integrating cloud services allows teams to analyze trends across the supplychain, correlate machine-level metrics with inventory movement, and run optimization models that would be cost-prohibitive at the edge. Cloud-based dashboards help stakeholders track throughput, compliance metrics, and performance benchmarks across plants.

Cloud integration also enables coordinated updates, large-scale machine learning training, and cross-site predictive models that enhance predictive maintenance programs. When combined with local fallbacks, cloud services extend functionality without compromising core control stability.

How do sensors and monitoring improve uptime?

Accurate, strategically placed sensors feed the data loops that enable condition monitoring and anomaly detection. High-frequency telemetry from vibration, temperature, pressure, and electrical sensors supports early detection of degradation that impacts throughput or energy use. Regular monitoring of these signals, with filtering at the edge and aggregation in the cloud, creates a layered view of asset health that fuels maintenance planning and reduces unplanned downtime.

Sensor data also supports inventory reconciliation and supplychain visibility by tracking material movement and equipment states. Reliable monitoring practices and standardized sensor interfaces make it easier to scale solutions across facilities while preserving consistency for compliance reporting.

How do analytics enable predictive maintenance?

Analytics combine historical trends, real-time monitoring, and domain knowledge to predict failures before they occur. Hybrid cloud approaches let lightweight inference run at the edge for immediate alerts and route richer model training workloads to the cloud where greater compute resources are available. Predictive maintenance reduces emergency repairs, balances maintenance windows against production schedules, and optimizes spare parts inventory to keep throughput steady.

Models should be validated continuously, with feedback loops that integrate maintenance records and energy usage patterns so analytics remain relevant. Transparent model governance supports compliance and helps operations trust automated recommendations.

How does cybersecurity protect control systems?

A hybrid design reduces exposure by keeping critical control logic local and minimizing the attack surface of cloud-connected components. Security controls include network segmentation, robust identity and access management, encrypted telemetry between edge and cloud, and continuous monitoring for anomalous activity. Ensuring device integrity for sensors and edge controllers prevents adversarial manipulation that could disrupt throughput or falsify inventory and supplychain data.

Regular patching, secure boot mechanisms, and least-privilege policies are essential. Security practices must be integrated into deployment and operational procedures to meet regulatory compliance and to maintain resilience against both cyber and physical threats.

How do automation and optimization affect throughput and supplychain?

Automation coordinates equipment and material flows to maximize throughput and reduce waste. Hybrid cloud architectures enable local control sequences to maintain cycle times while cloud-driven optimization suggests cross-site scheduling, resource allocation, and energy management strategies. Combining local deterministic automation with global optimization improves on-time delivery and aligns inventory levels with demand forecasts.

Optimization workflows can use analytics to balance production speed against energy costs and maintenance windows. Maintaining clear operational boundaries—what runs at the edge versus what runs in the cloud—ensures automation continues smoothly during connectivity variations while benefiting from aggregated, data-driven optimization.

Conclusion

Hybrid cloud approaches for control systems balance the immediacy and determinism of edge computing with the scale and analytic power of cloud platforms. By aligning sensors, monitoring, analytics, and cybersecurity practices, organizations can support predictive maintenance, optimize energy and throughput, and improve supplychain visibility without compromising compliance or local operational resilience. Thoughtful partitioning of workloads and continuous validation of models and controls are key to sustaining reliable industrial operations in hybrid environments.