Preventive Cleaning Routines to Minimize Thermal and Corrosion Risks

Regular, preventive cleaning routines help reduce heat buildup and slow corrosion on electronic devices. This article outlines practical, non-speculative steps for routine maintenance, safe hardware cleaning, cooling optimization, diagnostics, and lifecycle considerations to protect electronics and extend longevity.

Regular preventive cleaning is a practical way to reduce thermal buildup and slow corrosion in computers and electronic devices. Dust, conductive debris, and residue from humidity accelerate heat retention and create environments where corrosion can start. A scheduled approach that combines basic maintenance, careful hardware cleaning, firmware attention, and targeted diagnostics helps preserve performance, support compatibility with upgrades, and reduce the need for repair over the device lifecycle.

What routine maintenance reduces thermal risks?

A consistent maintenance schedule reduces heat-related failures. Monthly visual checks to remove dust from vents and fans, quarterly compressed-air cleaning of accessible interior surfaces, and biannual inspections of thermal pads and paste help keep components within design temperature ranges. Maintenance should also include firmware updates that can optimize fan curves and power management. Keep records of cleaning dates, observed temperatures, and any troubleshooting steps taken to build a lifecycle log that supports optimization and future repair decisions.

How should hardware be cleaned and inspected?

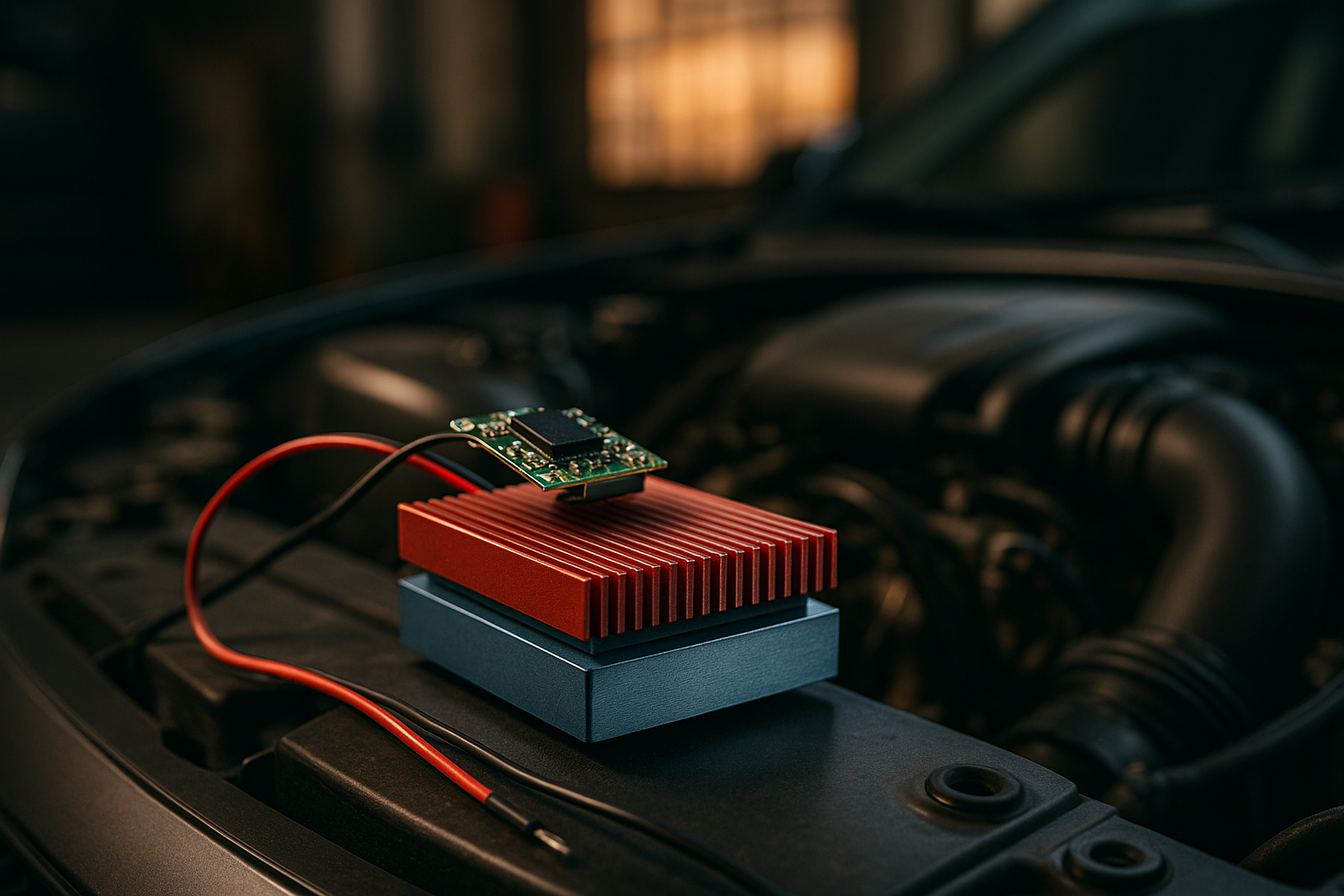

Hardware cleaning should be done with anti-static precautions and gentle tools: a soft brush, lint-free cloths, and low-pressure canned air or an electric blower. For laptops and desktops, remove the case where recommended and clean heatsinks, fan blades, and intake filters. Inspect connectors, ports, and battery compartments for signs of residue, oxidation, or moisture. If uncertain, consult local services or a qualified technician for deeper disassembly. Proper cleaning also supports security by preventing contaminants from interfering with physical ports and connectors.

When should firmware and upgrades be considered?

Firmware updates can provide improved thermal and power management profiles, which reduces thermal stress on hardware. Before applying firmware or other upgrades, confirm compatibility with existing components and backup important data. Firmware that optimizes fan curves or power scaling may reduce average operating temperatures; however, updates should come from verified sources to avoid security risks. Upgrades to more efficient power supplies or cooling components can also be scheduled alongside routine cleaning to maximize the benefits of both interventions.

How can cooling systems be optimized?

Cooling optimization combines cleaning with component choices and settings. Ensure airflow is unobstructed, cables are routed to avoid dead zones, and intake/exhaust directions follow manufacturer guidance. Replace degraded thermal paste on CPUs or GPUs as part of planned maintenance, and consider filter installation for environments prone to dust. For systems in humid or coastal locations, desiccant packs in storage enclosures and regular inspections help reduce corrosion risk. Optimization should balance noise, power, and thermal performance according to the device’s intended use.

What power checks prevent corrosion and failures?

Power irregularities can accelerate corrosion and damage components. Regularly inspect power bricks, cords, and surge protectors for wear, discoloration, or loose contacts. Test UPS or backup systems periodically and verify that grounding is intact. In environments with frequent outages or voltage spikes, consider power conditioning or regulated supplies. Proper power management through firmware and operating system settings can reduce constant high-load conditions that raise component temperatures and increase the chance of thermal-driven degradation.

Which diagnostics help identify corrosion or heat damage?

Run hardware diagnostics that report temperatures, fan speeds, and error logs to catch rising trends before failures occur. Visual inspections for green or white corrosion deposits, pitting on contacts, or flaky solder indicate early corrosion. Use diagnostics tools for stress testing and thermal profiling, but avoid prolonged stress that could worsen existing issues. Troubleshooting steps should isolate whether a fault is hardware, firmware, or power-related to guide repair, recycling decisions, or compatibility checks for upgrades.

Incorporating recycling and repair pathways into preventive routines reduces waste when components reach end of life. When cleaning reveals irreparable corrosion or thermal damage, document the condition and pursue certified repair or recycling options that comply with local services and regulations. Keeping devices patched and secure helps prevent software-induced stress on hardware, and planning for compatibility during upgrades minimizes lifecycle disruption. Consistent preventive cleaning and monitoring support longer, safer service life and reduce the likelihood of unexpected failures.

Regular preventive cleaning routines, combined with firmware management, careful hardware inspections, power stabilization, and targeted diagnostics, form a cohesive strategy to minimize thermal stress and corrosion over a device’s lifecycle. Applying these steps consistently supports optimization, reduces repair frequency, and extends longevity without relying on speculative claims or unnecessary interventions.